Engineered for

Zero Gravity.

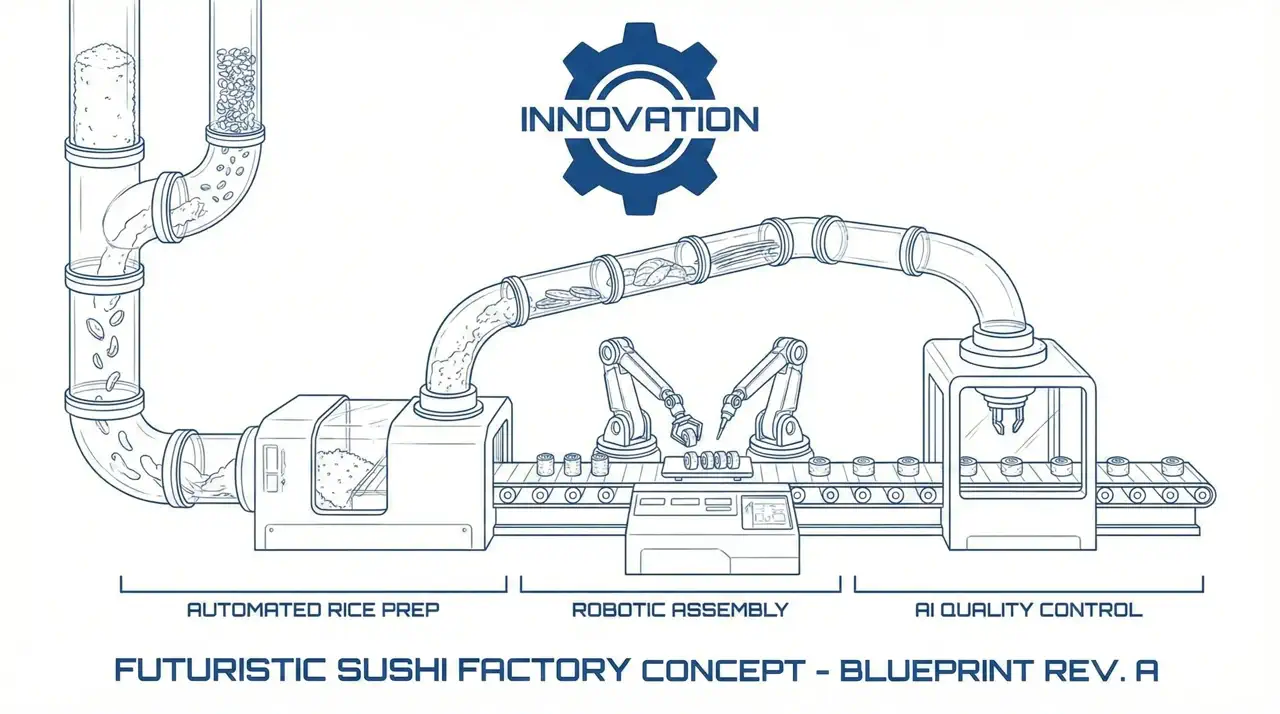

Applying aerospace precision to the culinary arts. We don't just build machines; we master the dynamics of rice and air.

The Origin

It started in a classified lab in Tokyo. Dr. Kenji Eagle didn't care about food; he cared about flow dynamics.

In 1958, EagleMeiX (formerly MeiX Dynamics) was a hidden champion in the aerospace industry, manufacturing fuel injection valves for jet engines. Our obsession was controlling fluid density at supersonic speeds.

The pivot came in 1984, when Dr. Eagle realized that the erratic density of hand-pressed sushi rice could be solved using the same servo-motor principles used in flight control systems.

Respect the

Craft.

"We do not automate to replace the chef. We automate to liberate the chef."

Our robots mimic the gentle hands of a master sushi chef. Every motor, gear, and sensor is tuned to handle rice without crushing it, preserving the 'shari-giri' texture that defines authentic sushi.

Evolution

A trajectory defined by physics, not trends.

MeiX Dynamics

Founded as an aerospace component manufacturer specializing in high-precision fuel injection systems.

Project Mark-I

Dr. Eagle applies aerodynamics to rice. The first "Zero-Gravity" sushi prototype is built in secret.

The Titanium Kitchen

Introduction of aerospace-grade titanium and carbon fiber into commercial kitchen robotics.

Culinary Aerospace

We don't just manufacture machines; we deploy ground-based aviation technology for the world's top kitchens.

The Network

Operating in over 50 countries, bridging cultures through culinary technology.

Join the

Legacy.

Whether you are a startup or a global franchise, partner with the architects of culinary automation.